Understanding Fiber Optic Cable Construction and Types: A Deep Dive into the World of Optical Communication

As technology advances at a rapid pace, the demand for high-speed and reliable communication networks has never been greater. Fiber optic cables have emerged as the backbone of modern telecommunications, enabling the transmission of vast amounts of data over long distances at incredible speeds. To better comprehend the intricacies of fiber optic cables, it is crucial to grasp their construction and the different types available. This article aims to provide a comprehensive understanding of fiber optic cable construction and types, empowering you with knowledge to make informed decisions in the dynamic world of optical communication.

Chapter 1: Fiber Optic Cable Construction

Fiber optic cables are composed of minuscule strands of glass or plastic called optical fibers. These fibers are coated with protective layers to enhance their durability and prevent signal loss. The basic construction of a fiber optic cable involves three main components:

- Core: The innermost section of the cable, consisting of one or more optical fibers. It serves as the pathway for transmitting light signals.

- Cladding: A layer surrounding the core, designed to reflect light back into the core, allowing it to travel through the fiber with minimal loss.

- Jacket: The outermost layer that protects the core and cladding from environmental factors such as moisture, temperature variations, and physical damage.

Chapter 2: Single-mode vs. Multimode Fiber Optic Cables

Single-mode Fiber Optic Cable:

Single-mode fiber optic cables are primarily used for long-distance communication. They have a smaller core diameter, typically around 8 to 10 microns, which allows a single beam of light to travel directly down the center of the fiber with minimal dispersion. This type of cable offers higher bandwidth and lower attenuation, making it ideal for applications that demand high data rates and low signal loss.

Multimode Fiber Optic Cable:

Multimode fiber optic cables are suitable for shorter distance communications. They have a larger core diameter, typically ranging from 50 to 62.5 microns, which supports the transmission of multiple light rays or modes simultaneously. However, multimode cables experience higher dispersion and attenuation compared to single-mode cables, limiting their bandwidth and transmission distance.

Chapter 3: Loose Tube vs. Tight Buffered Fiber Optic Cables

Loose Tube Fiber Optic Cable:

Loose tube fiber optic cables employ a design where the optical fibers are contained within flexible, gel-filled tubes. This construction provides superior protection against moisture, harsh environmental conditions, and physical damage. Loose tube cables are commonly used in outdoor and long-haul applications where durability is paramount.

Tight Buffered Fiber Optic Cable:

Tight buffered fiber optic cables, on the other hand, have the optical fibers directly coated with a layer of protective material. This design simplifies cable termination, making it more suitable for indoor applications and shorter distances. The tight buffer adds an extra layer of protection against mechanical stress, making it less prone to damage during installation and handling.

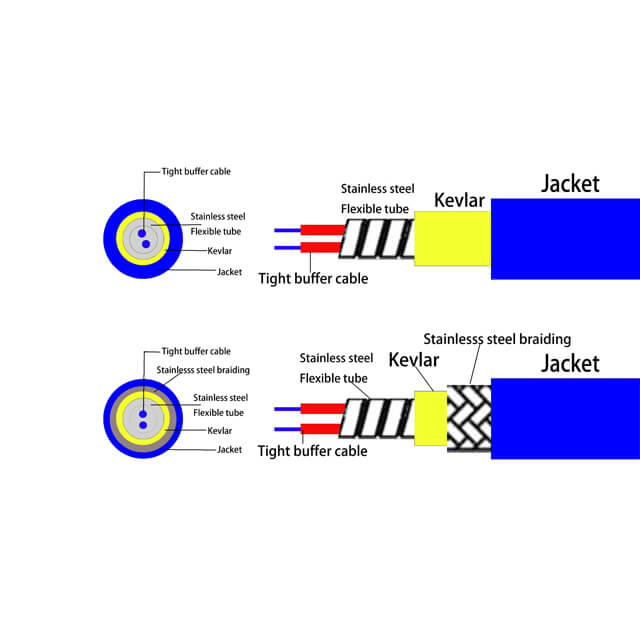

Chapter 4: Armored vs. Non-Armored Fiber Optic Cables

Armored Fiber Optic Cable:

Armored fiber optic cables are reinforced with an additional layer of armor, typically made of steel or aluminum. This armoring provides enhanced protection against rodent damage, crushing forces, and other external threats. Armored cables find widespread use in harsh environments such as industrial facilities, outdoor installations, and areas prone to physical disturbances.

Non-Armored Fiber Optic Cable:

Non-armored fiber optic cables lack the additional layer of armor and are more flexible and lightweight compared to their armored counterparts. They are typically used in controlled environments such as indoor installations or where external protection is not a primary concern. Non-armored cables offer greater flexibility, making them easier to install and maneuver.

Chapter 5: Specialty Fiber Optic Cables

Breakout Fiber Optic Cable:

Breakout fiber optic cables consist of multiple tight buffered fibers bundled together within a single jacket. They are frequently used in applications that require higher fiber counts and individual fiber access.

Ribbon Fiber Optic Cable:

Ribbon fiber optic cables contain multiple fibers arranged in a flat ribbon-like structure. This design allows for high-density installations, as the ribbon fibers can be spliced together simultaneously, saving time and reducing installation costs.

Aerial Fiber Optic Cable:

Aerial fiber optic cables are specifically designed for installation on utility poles, rooftops, or other elevated structures. They possess additional strength members or an integrated messenger wire to facilitate secure suspension over long spans.

Understanding fiber optic cable construction and the different types available is indispensable in navigating the vast world of optical communication. Armed with this knowledge, you are now equipped to make informed decisions when selecting the appropriate fiber optic cable for your specific application. Whether you require high-speed data transmission, durability in harsh environments, or cost-effective installation, there is a fiber optic cable construction and type tailored to meet your needs.