There are various types of fiber optic cables available on the market, differing in size, shape, color, structure, and material. Choosing the right fiber optic cable can be challenging, but this article offers some tips to help you make the best decision.

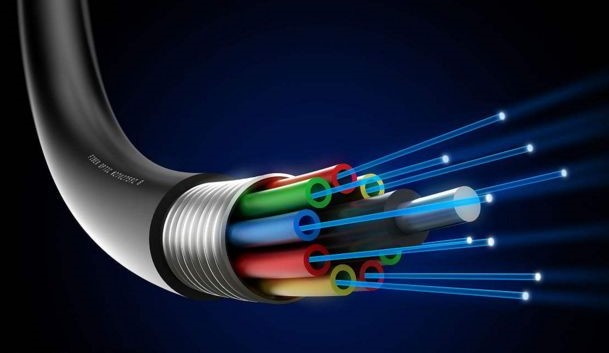

What is Fiber Optic Cable?

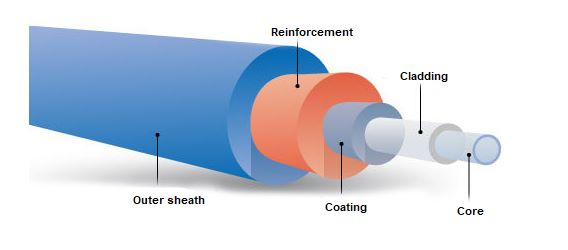

Fiber optic cables transmit data in the form of light pulses through flexible, optically pure glass. These cables consist of five main components: the core, cladding, coating, strength members, and outer jacket.

- Core: Made of high-purity silica (SiO2) with a small amount of dopants, the core is responsible for transmitting light pulses generated by lasers or light-emitting diodes (LEDs).

- Cladding: This thin layer of glass surrounds the core and has a different refractive index to reflect light back into the core, allowing the signal to propagate.

- Coating: Designed to absorb shock, prevent excessive bending, and protect the core.

- Strength Members: These components shield the core from excessive tension and compression, particularly during installation.

- Outer Jacket: Provides protection from external factors like shock, moisture, and other environmental influences.

Tips for Choosing the Right Fiber Optic Cable

1. Cable Type

First, determine whether you need single-mode (SM) or multimode (MM) fiber optic cable based on your network application and specifications. Generally, SM fiber is ideal for long-distance and outdoor applications, while MM fiber is suited for short-distance and indoor use.

2. Fiber Core Count

After selecting the fiber type, calculate the number of fibers needed for your network. This depends on the scale of your FTTX (Fiber to the x) and ODN (Optical Distribution Network) projects and the type of fiber optic cable you plan to use. Backbone cables typically range from 24 to 288 cores, while distribution cables require fewer cores. FTTH home cables usually have 1 or 2 cores.

3. Deployment Environment

Consider the structure and material of the fiber optic cable based on its deployment location:

- Outdoor:

For direct burial, loose tube layer-stranded armored fiber optic cables offer the best protection. In overhead environments, self-supporting cables that can bear their own weight, such as figure-8 or ADSS cables, are ideal.

- Indoor:

Flame-retardant, low-smoke, halogen-free (LSZH) cables are essential for indoor use. In duct environments, choose cables with flame-retardant and LSZH properties. For exposed indoor environments, the same LSZH cables are required. Tight-buffered optical fibers, known for their small bending diameter, softness, and easy stripping, are well-suited for indoor applications.

- Buildings:

When laying cables vertically or horizontally within a building, tight-buffered, bundled (D-type), or branched (B-type) optical cables are recommended.

4. Connectors

Connectors are crucial for establishing a secure fiber optic network. Common types include ST, FC, SC, LC, and MTP/MPO connectors.

- ST: Popular in telecommunication networks, spring-loaded for easy connection and removal.

- FC: Threaded body, ideal for high-vibration environments, polarized fiber, and SM fiber.

- SC: Snap-on connector, commonly used in SM fiber, duplex networks, CATV, media converters, and FTTX.

- LC: A standard ceramic ferrule connector, half the size of SC, used in SM fiber, data centers, LANs, FTTH, and CATV.

- MTP/MPO: High-performance multi-core connectors for data centers.

Summary

When selecting a fiber optic cable, consider the cable type, fiber core count, deployment environment, and connectors. By evaluating these factors, you can confidently choose the most suitable fiber optic cable for your needs.